Summary:

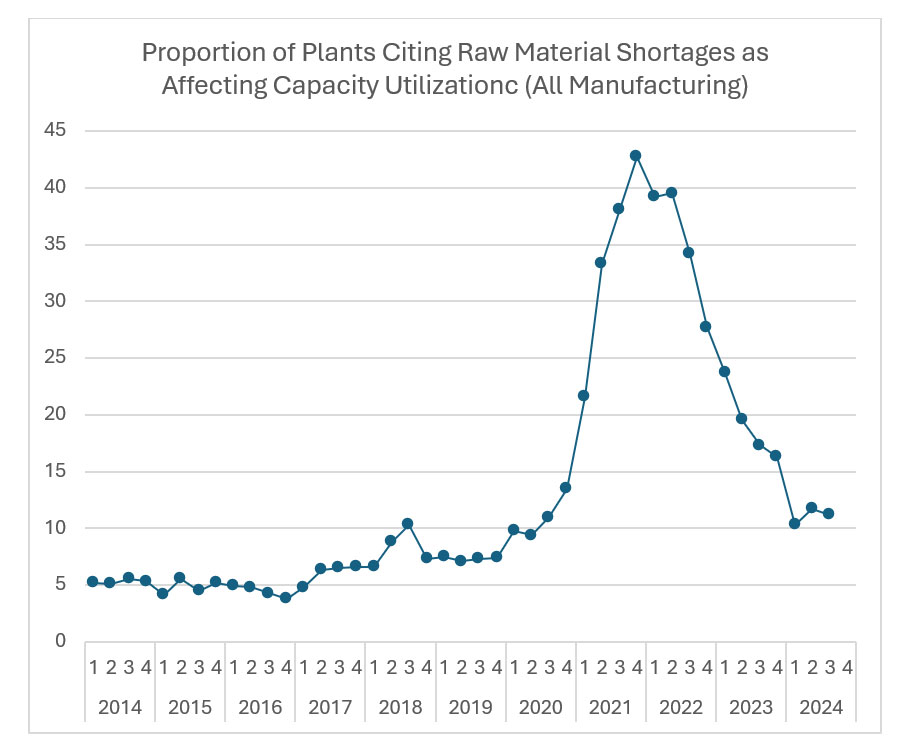

In 2025, apparel factories are navigating a volatile world of geopolitical risks, tariffs, logistics disruptions and raw-material shortages. These external shocks amplify the vulnerabilities of factories that already face cost and demand pressure.

Key pain points:

● Tariff risk and sourcing shifts: With trade policies changing fast, factories face shifting orders, re-routing sourcing, higher logistics and duty costs.

● Raw-material & shipping bottlenecks: Inflation, supply chain hiccups mean higher cost of fabric and trims, and delayed deliveries.

● Need for agility and diversification: Factories tied to one region or one major buyer are exposed. Diversification of sourcing markets, clients and production sites is increasingly essential.

● Cash-flow & financing stress: Smaller factories may lack working capital to absorb delays or retool for new sourcing routes.

Why this matters for you:

As a designer working closely with factories, you must understand that your supply chain may no longer be stable. Design timelines, sourcing assumptions, changeovers – all must account for higher risk. Factories that cannot pivot may lose designs/brands.

Outlook & advice:

● Encourage factories to map alternate supply routes, backup suppliers, and build resilience.

● In design planning, allow for buffer time, flexible sourcing of fabrics and components.

● Consider near-shoring or regional production to reduce dependence on distant logistics.

● Monitor cost spikes and pass-throughs; the “factory cost” baseline is more uncertain.

Reference link: Fashion supply chains – 2025 risks and trends (Feb 2025)

Post time: Oct-29-2025